Introduction

This course is delivered directly by PaperClassroom and for other organisations such as Paper Technics. Over the two days we take an overview of the paper, board and tissue industries.

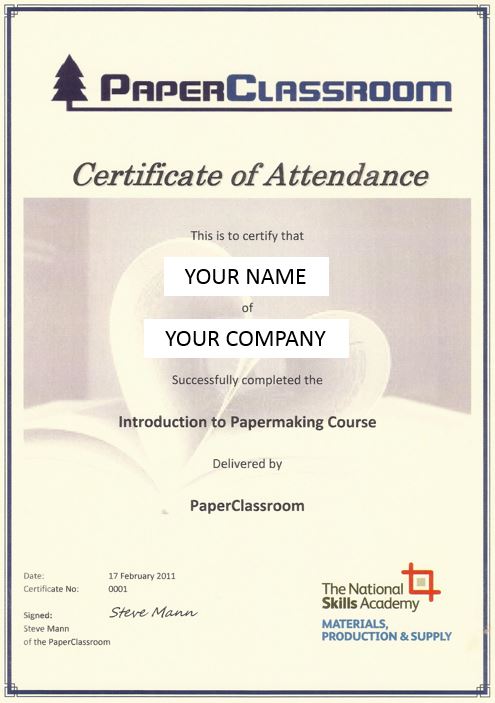

We have a lot of fun in this 2-day course. As well as getting a certificate like the one above, you will:

- receive full colour, full text notes

- see video clips of other paper mills

- look at and understand different types of paper

- have a look at model fibres to help you understand

- have a go at making your own fibres

- play some fun games

1 Day Programme

- Papermaking Chronology and Trends Key dates and inventions. Who is making and who is using paper today?

- Raw materials What fibres and chemicals are used in papermaking. The importance of water.

- Working on fibres What does the mill do to fibres to make the right type of paper?.

- LUNCH

- Making paper and board How single ply paper and multiply boards are formed.

- Making tissue Why does tissue feel so soft?

- Water removal How the water is squeezed out of the sheet. Multicyllinder drying methods

- Finishing and converting Changing the surface of paper, cutting it into sheets and reels

- Paper properties and defects Why paper for bags, boxes and bottoms needs to be different!

2 Day programme

- History of Papermaking and Market Trends A colourful, scene setting journey through time. How are the wasp, the black death and Egyption mummies connected to papermaking?. What types of paper are there? Who is making paper and who is using paper today?

- Fibres What types of plants do we get fibres from? Where do they grow? How are they different? How do we match the fibre to the end product?

- Water What type of water do we use? What problems can it cause? Why do we rectcle it?

- Chemicals Explains the different types of chemicals used in the paper industry. Some are there to improve the process of making paper, while others are there to change the properties of the sheet.

- LUNCH

- Enzymes What are enzymes and why are they finding increasing use in the paper tidustry.

- Stock Preparation Looks at how we work on fibres to change their properties, in order to make the right end product. We also look at the equipment we use to do this.

- Approach Flow Learn how the stock is blended, cleaned and diluted prior to entering the flowbox.

- The Flow Box See the history of the flow box and see just how we squirt those fibres onto the fast moving forming fabric

- Paper and Board Formation See and understand how single layer paper and multilayer boards are produced on different types of equipment

- DAY 2

- Tissue Formation Gain an awareness of different types of tissue, how tissue productiuon is different from paper and board production and just why tissue can feel so soft

- Pressing See how pressing works and understand why it is so important today

- Drying Drying is the most expensive part of the paper manufacturing process. Learn how we do it.

- Finishing The finishing process involves the surface treatment of paper. Learn how jumbo reels are cut down into smaller sizes, turned into sheets, made glossier or embossed.

- LUNCH

- Converting This step is usually carried out away from the mill and can include corrugating, parchmentising, laminating and more...

- Process Control There is a 3-year degree in process control! But here, we simply tell you in every day language, what it is all about. A jargon buster session.

- Paper Properties and Defects You have now had two days of papermaking. Here we take a look at paper properties and it should all make sense!

Contact

The easiest wy to contact me is via email to steve@paperclassroom.com

Skype ID: drzirconium

Mobile: +44 (0)7780 614148

Within the UK first consultation visits are free